QUALITY CONTROL

Our aluminum raw materials and the chemical alloys of the produced profiles are analyzed with our SPECTRAL ANALYSIS device. HARDNESS MEASUREMENT after the aging process is made with hardness measuring pliers.

After surface treatments, PAINT THICKNESS and ANODIZING COATING THICKNESS are measured with a micron thickness measuring device and a stain test is applied for anodized profiles under the control of our chemical engineer.

Painted profiles are also subjected to IMPACT TEST and SALT TEST by sending samples to our supplier paint companies, and the results are reported by the R&D Laboratory.

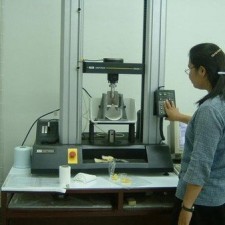

Tensile test is applied to our products in KOSGEB/SMEDO Laboratory and yield, tensile and elongation values are reported according to TS prEN 754-2.

.